Loading... Please wait...

Loading... Please wait...Safety Orange Replacement Strip Door Strips

Product Description

Safety Orange Highlights the outer edges of the Door Opening, alerting employees and improving safety.

Recommended as the outer edge Strips for Strip Doors with motorized traffic.

If you have any Questions regarding any aspect of selecting the proper vinyl strips for your needs,

Please use the blue "Ask The Pro" feature button below or feel free to call us at 800-982-6966. We will be happy to assist you.

For more sizes (width of strips) Select HERE (change link).

How to Order: Ameri-Brand Flexible Safety Orange Replacement Strips.

Use the simple 3 Step checklist below, to be sure you will receive the correct product for your needs.

1st, a little comparative shopping ......

Here's Why Our Strip Doors are Better.

and, you can SEE the QUALITY.

Selection and Ordering:

Step 1. Height and Width of the Opening:

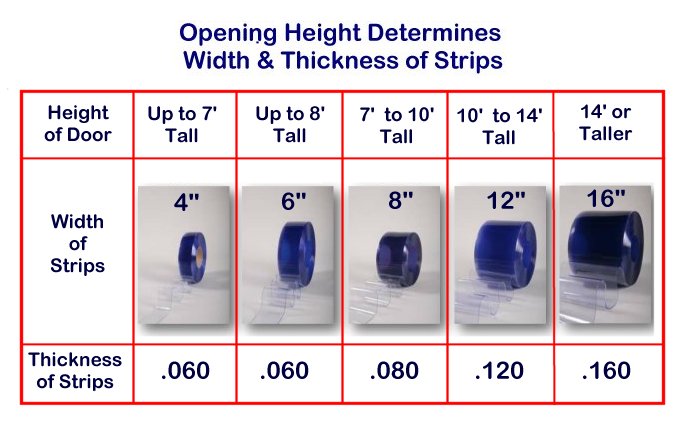

The height of the door opening determines the width and the thickness of the strips. Typically, the taller the door is the thicker the strips need to be and also the taller the door the wider the strips are.

You can use the chart below to determine the proper width and the thickness of strips needed for your application.

NOTE: The available door width sizes are shown in the "Dropdown" menus above. Some of the sizes are available in progressive 6" increments.

Example widths: 4', 4-6", 5', 5-6", 6', 6-6", etc.

Order the exact size you need or round up to the next largest size if your coverage area dictates. As shown in the strip door installation video, the track is easily cut at the installation site if the size needs to be reduced.

Not sure about the proper thickness you need?

Here's some more information on Strip Door gauge or thickness.

|

Click Size to See Comparisons |

|||

Step 2. Temperature Requirements:

In general, softer strips are needed for colder temperatures. The softer materials remain flexible in cold temperatures, and are better able to resist brittleness, cracking, and breaking. Our strips have proven to be the most flexible in North America! (More than 20% SOFTER than the nearest competitor)

Type 1 = Standard Strips. These are normally used in -10 degrees to +150 degrees farenheight. Type 1 strips are used in most applications including typical walk-in freezers and refrigerators.

Type 2 = Low-Temp Strips. Used for EXTREMELY LOW temperatures down to -40 degrees farenheight.

If purchasing the the Type 2 strips, you may want to consider the use of the nylon fiber reinforced panels. This can help to prevent strips from shrinking or elongating in extremely cold conditions.

Step 3. How to determine strip overlap percentage:

NOTE: The Strip overlap relates to the amount of strip that overlaps its neighboring strip(s) and is expressed as a percentage of the amount of overlap one strip will cover the neighboring strip.

Pedestrian or "Walk Thru" Traffic - Vinyl strip doors with walk-thru traffic should use smaller size strips with less overlap. A 6" with a 67% overlap or an 8" strip with 50% overlap works well. 4" strips should be used on very small openings (4' wide or less) with walk-thru traffic only. FYI, smaller strips provide less wind resistance and do not hold up as well under heavy forklift traffic.

Pallet Jacks and Carts - Pallet Jack and Cart usage usually means that the loads will be larger and that the traffic will be heavier. This type of traffic will usually have a have a person walking with the load. If an you anticipate both the heavy pallet and accompanying personal usage, you may want to use 6" wide strips with a 67% overlap, or 8" wide strips with a 50% overlap.

Forklift and Tractor Traffic - This is pretty tough traffic. It will wear more quickly on strip door systems. Use larger strips for this application. If the cargo is lightweight, the larger strips may tend to drag or pull product off the pallet. An 8" material with 50% to 100% overlap or 12" material with 25% to 50% overlap.

Size of Opening Vs. Size of Load - If the opening is small in relation to the size of the load, you may want to consider using smaller strips with less overlap as the strips are more prone to dragging items off of the load. For example, consider 8" material versus 12" material on a 96" high opening with an 84" high load.

Larger vinyl strips and /or more overlap should be considered for the larger doors or when windy or drafty conditions may be a factor.

Very windy or "Negative Air Pressure" applications may require a higher percentage of strip overlap.

For more sizes (width of strips) Select HERE.

Again,

If you have any Questions regarding any aspect of selecting the proper vinyl strip door kit for your needs,